Elektromagnetische Durchflussmesser, oft als Magenmeter bekannt, prüfen, wie schnell Flüssigkeiten, die den Stromstrom leiten. Sie verwenden eine wissenschaftliche Idee namens Faradays Gesetz der elektromagnetischen Induktion. Dies erzeugt einen kleinen elektrischen Funken, basierend darauf, wie schnell sich die Flüssigkeit bewegt. Diese Zähler haben keine Teile, die sich bewegen, so dass sie hart und einfach zu pflegen sind. Sie sind ideal für Orte wie Wasserreinigungsanlagen, Chemieladen und Lebensmittelfabriken. Chen Shuo baut erstklassige Meter mit coolen Tricks wie Lärmreduzierung und Internetverbindung. Aber sie arbeiten nur mit Flüssigkeiten, die Strom tragen und sorgfältige Einrichtung benötigen, wie eine richtige Erdung und gerade Rohrabschnitte.

Mag-Zähler sind Gadgets, die die Menge an leitfähiger Flüssigkeit bestimmen. Sie verwenden eine natürliche Sache, die elektromagnetische Induktion genannt wird. Wenn eine Flüssigkeit, die Elektrizität tragen kann, durch ein Magnetfeld passiert, macht sie ein kleines elektrisches Signal. Dieses Signal sagt uns die Geschwindigkeit der Flüssigkeit. Im Gegensatz zu alten Zählern mit drehenden Teilen haben Magenmeter keine beweglichen Teile im Rohr. Dies macht sie zuverlässig, senkt Druckfälle und bedeutet weniger Fixierarbeit.

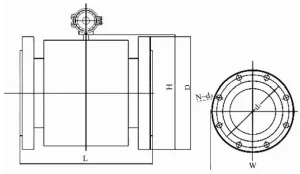

Ein Magenmeter hat einige Hauptteile, die sich zusammenstellen. Dies sind eine Anregungsspule, Elektroden, ein Messrohr und ein Wandler. Die Spule erzeugt ein Magnetfeld. Elektroden, die an den Seiten des Rohres feststecken, greifen das elektrische Signal, das die Flüssigkeit macht. Das Rohr hält die Flüssigkeit während sie fließt. Der Konverter ändert das Signal in Zahlen, die Sie sehen können. Jedes Stück ist der Schlüssel, um sauber zu werden, die richtigen Messungen.

Faradays Gesetz besagt, dass wenn sich etwas, das Elektrizität trägt, durch ein Magnetfeld bewegt, es ein elektrisches Signal erzeugt. Die Leistung des Signals hängt davon ab, wie schnell es geht. In Magenmetern verwandelt dieses Gesetz die Bewegung der Flüssigkeit in ein Signal, das wir überprüfen können. Es ist wie ein ordentlicher Trick, um festzustellen, wie schnell die Flüssigkeit fließt, ohne sie zu berühren.

Wenn eine Flüssigkeit, die Strom leitet, durch das Rohr fließt, durchquert sie ein Magnetfeld von der Anregungsspule. Diese Kreuzung erschüttert die magnetischen Linien und bildet ein winziges elektrisches Signal zwischen zwei Elektroden auf gegenüberliegenden Rohrseiten. Je schneller sich die Flüssigkeit bewegt, desto größer wird das Signal. Es ist eine einfache, aber intelligente Möglichkeit, den Fluss zu verfolgen.

Die Größe des Signals hängt von drei Dingen ab: der Leistung des Magnetfeldes (B), der durchschnittlichen Geschwindigkeit der Flüssigkeit (V) und der Größe des Rohres (D). Es gibt eine mathematische Regel dafür: E = K × B × V × D. Hier ist E das Signal und K eine feste Zahl. Das bedeutet, dass das Signal stärker wird, wenn sich die Flüssigkeit beschleunigt oder das Rohr größer ist.

Innerhalb des Sensors des Zählers bildet die Anregungsspule ein konstantes Magnetfeld. Dieses Feld durchquert das Rohr in einem Winkel von 90 Grad zum Pfad der Flüssigkeit. Es bildet einen guten Ort, um ein Signal zu erzeugen, wenn die Flüssigkeit durchströmt.

Wenn sich die Flüssigkeit durch diesen magnetischen Fleck bewegt, schneidet sie durch die magnetischen Linien. Diese Bewegung erzeugt ein kleines elektrisches Signal zwischen den Elektroden. Das Signal ist super klein, aber ausreichend, um die Geschwindigkeit der Flüssigkeit zu zeigen.

Die Elektroden erfassen das Signal und senden es über Drähte an den Wandler. Der Konverter wirkt wie ein cleveres Gehirn. Es liest das Signal, macht einige schnelle Mathematik und zeigt die Ergebnisse. Sie können den Gesamtfluss in der einen Richtung, den Gesamtfluss in der anderen Richtung und die aktuelle Strömungsgeschwindigkeit auf einem Display sehen. Es ist klar und wirklich nützlich.

Mag Meter sind super genau, in der Regel innerhalb von ±0,5% von der Flussgeschwindigkeit. Sie bleiben spot-on, auch wenn sich der Durchfluss sehr verschiebt. Dies macht sie großartig für Aufgaben, die perfekte Zahlen benötigen, wie in Fabriken oder Wasseranlagen. Sie sind stark und arbeiten an vielen Orten gut.

Da Magenmeter keine beweglichen Bits oder Blöcke im Rohr haben, brechen sie nicht viel ab. Sie werden nicht mit Schmutz, Stücken oder dicken Dingen wie Schlamm feststecken. Dies bedeutet, dass Sie sie weniger reparieren und Zeit und Geld sparen.

Mag Meter sind in vielen Bereichen wirklich praktisch. Sie sehen sie in Chemiefabriken, Wasserreinigungsanlagen, Lebensmittelherstellungsstellen, landwirtschaftlichen Wassersystemen, Kraftwerken und vielem mehr. Sie sind hart und biegsam, was sie zu einem Favoriten für viele Jobs macht.

Magzähler arbeiten nur mit Flüssigkeiten, die Strom tragen, wie Wasser oder Schlammmischungen. Flüssigkeiten wie Öl leiten nicht, so dass sie kein Signal senden. Das bedeutet, dass Magenmeter sie nicht verfolgen können.

Wenn Sie den Zähler nicht richtig einstellen, können Sie falsche Zahlen bekommen. Zum Beispiel lässt eine schlechte Erdung den statischen Strom das Signal zerstören. Außerdem benötigen Sie gerade Rohre vor und nach dem Zähler, um den Durchfluss gleichmäßig zu halten. Ohne diese kann der Zähler nicht sein Bestes tun.

Wenn Sie feste Durchflussmesser für große Wasserprojekte oder harte Fabrikarbeiten möchten, Chen Shuo Sie fertigen High-Tech-Zähler mit Tonnen von Erfahrung. Ihre Ausrüstung passt sowohl zum Wasserbedarf kleiner Städte als auch zu großen industriellen Jobs.

Chen Shuo verfügt über kompakte Zähler für enge Stellen, ideal für Stadtwassersysteme, die genaue Low-Flow-Kontrollen wünschen. Für raue Orte wie Chemie- oder Lebensmittelanlagen bekämpfen ihre robusten Meter Rost und erfüllen saubere Regeln.

Chen Shuos Meter sind super scharf, auch bei langsamen Flüssigkeiten. Dies ist perfekt für Leckagen oder winzige Strömungen. Sie haben auch clevere Tricks, um Lärm zu stoppen und die Messungen sauber zu halten. Darüber hinaus können ihre Zähler die Leitfähigkeit testen und sich frühzeitig auf Probleme prüfen. Sie können kleine Modelle für enge Räume wählen, ohne Stromverlust.

Die Erdung ist wirklich groß. Flüssigkeiten, die sich durch Rohre bewegen, können statischen Strom tragen, der Messungen abwerft. Halten Sie sich an Chen Shuos Erdungstipps, um Signale rein und Zahlen richtig zu halten.

Gerade Rohre vor und nach dem Zähler halten die Flüssigkeit gut fließen. Dies verhindert Drehungen oder ungleichmäßigen Fluss, der die Arbeit des Zählers verschmutzen könnte. Es ist super wichtig, wenn der Druck herumspringt.

Testen und tweak Ihr Meter oft, um es tot zu halten. Dies ist extra groß, wenn die Gesetze sagen, dass Sie super wahre Aufzeichnungen brauchen. Die Kalibrierung hält den Meter jahrelang fest.

Ja, die Reinigung ist eine Brise. Ohne Bits, die das Rohr blockieren, können Sie die Elektroden abschrauben, ohne den Zähler auseinander zu ziehen. Das spart Zeit und hält die Dinge am Laufen.

Chen Shuos Magenmeter spielen gut mit neuer Technologie. Sie verwenden Standardverbindungen wie Modbus oder RS485 um mit intelligenten Fabriken oder SCADA-Bildschirmen zu chatten. Dies macht sie einfach zu anschließen.

Die eingebauten Tools können Informationen wie den Gesamtfluss oder die Durchflussraten speichern und teilen. Sie können sich die Leistung Ihres Setups jederzeit und von überall ansehen, was cool ist.

Q1: Kann ich ein elektromagnetisches Durchflussmesser mit ölbasierten Flüssigkeiten verwenden?

A: Nein, Magenmeter benötigen Flüssigkeiten, die führen, wie Wasser oder Schlamm. Öle tragen keinen Strom, also funktionieren sie nicht.

Q2: Was macht elektromagnetische Durchflussmesser großartig für Abwasserarbeiten?

A: Ihr offenes Design verhindert, dass sich Gunk verstopft. Sie brauchen auch wenig Pflege, so dass sie für Alter gut laufen.

Q3: Brauche ich lange gerade Rohre vor der Installation meines Zählers?

A: Ja, gerade Rohre halten den Fluss ruhig. Dies hilft dem Zähler, wahre Messungen ohne Schlucken zu geben.